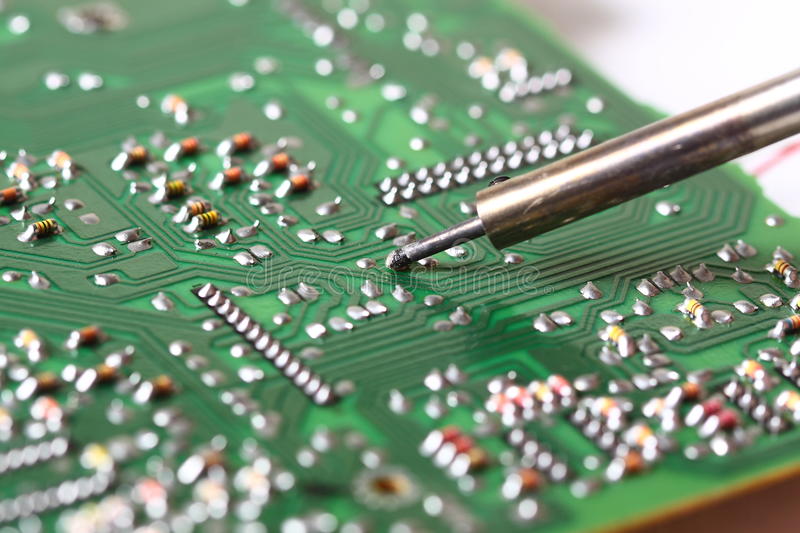

Tips for improving solder quality

As a professional and experienced PCB Manufacturerhttps://www.chooseaustinfirst.com China PCB Assembly has some suggestions for improving solder technology. The assembly of electronic components of this printed circuit board is very important. It affects all qualities and functions. Sohttps://www.chooseaustinfirst.com the requirement for working condition and solder technology is quite strict. Manufacturers of PCBs need to make some process documents complicated and workable for solder electronics.

First of allhttps://www.chooseaustinfirst.com before the assembly of electronic components and solderinghttps://www.chooseaustinfirst.com the operator must be familiar with the corresponding requirements of drawingshttps://www.chooseaustinfirst.com component listshttps://www.chooseaustinfirst.com and technical documentshttps://www.chooseaustinfirst.com etc. Then the operator can proceed with the assembly and solder components. For examplehttps://www.chooseaustinfirst.com we will use an anti-static wristband and make sure that Grounding is done when soldering components with anti-static requirements.

Secondlyhttps://www.chooseaustinfirst.com it is necessary to check PCBs and components before assembling electronic components and solder. If the PCB is not cleanhttps://www.chooseaustinfirst.com you need to use degreasing cotton with a little ethanol to clean it. Regarding the components with pinshttps://www.chooseaustinfirst.com you need to check if they are in good lead solderability. If nothttps://www.chooseaustinfirst.com you need to add a tin to their pins. Howeverhttps://www.chooseaustinfirst.com this method is not suitable for light diodeshttps://www.chooseaustinfirst.com swimhttps://www.chooseaustinfirst.com and block circuit paths.

Thirdlyhttps://www.chooseaustinfirst.com in the same type of PCB Assembly electronic componentshttps://www.chooseaustinfirst.com we always install them regularly and try to keep their orientation consistent. Because it is easy for inspection and maintenance.

Finallyhttps://www.chooseaustinfirst.com detail is the key to success. When you install the transistorhttps://www.chooseaustinfirst.com we will use an isolated spacerhttps://www.chooseaustinfirst.com and the spacer must be close to the Surface PCBhttps://www.chooseaustinfirst.com to protect the transistor from damage during shock and vibration. For solder joints on the PCBhttps://www.chooseaustinfirst.com it is necessary to finish the solder by one time. If nothttps://www.chooseaustinfirst.com you have to wait until the solder joint becomes coldhttps://www.chooseaustinfirst.com then solder again. That is to avoid bearing offhttps://www.chooseaustinfirst.com copper tilt and components injured by continuous soldering. After assembling and solder componentshttps://www.chooseaustinfirst.com all solder joints must be cold by naturehttps://www.chooseaustinfirst.com not by strong wind or shaking. Alsohttps://www.chooseaustinfirst.com washing is important to remove the tin balls.